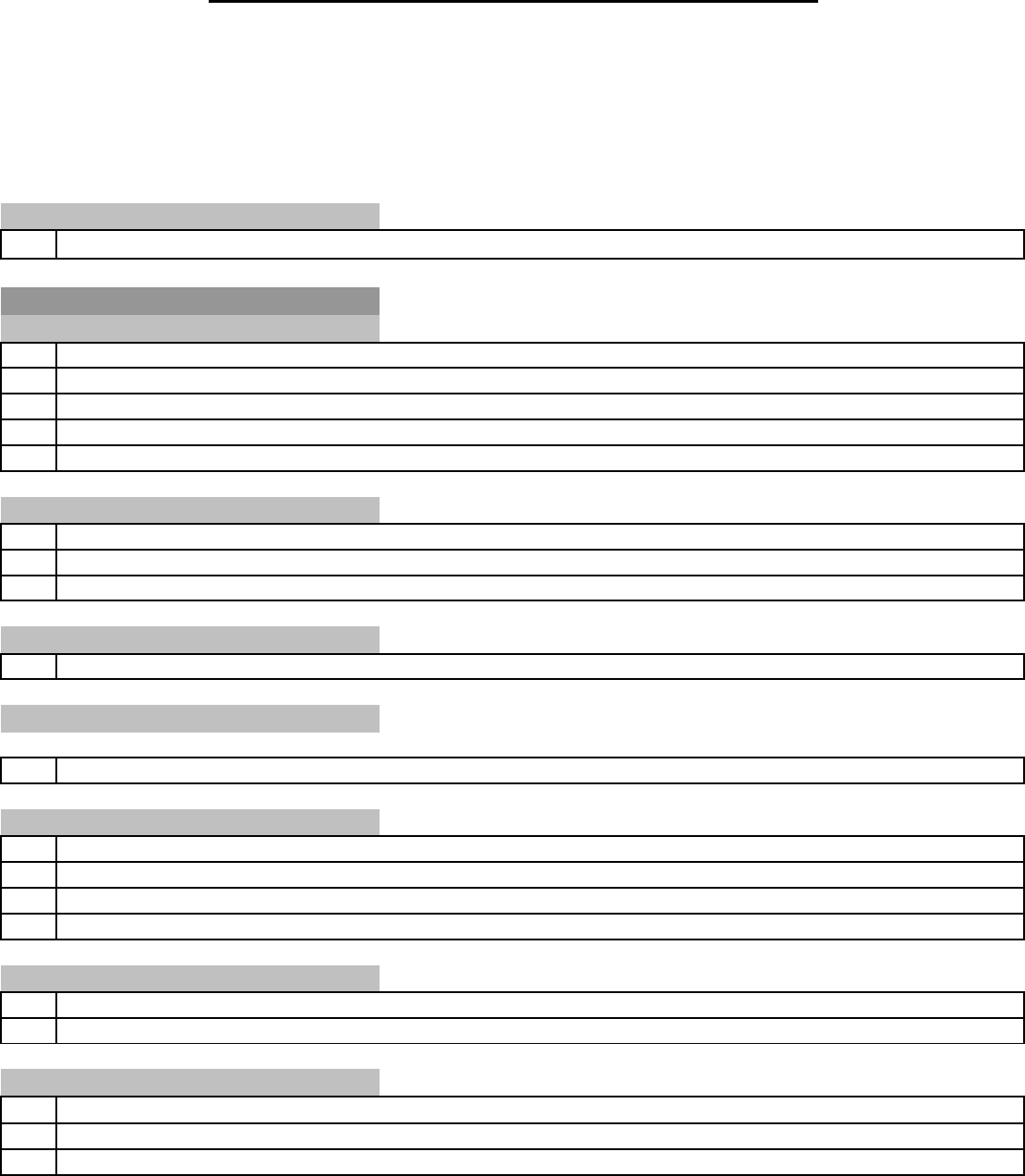

HTML Preview Weekly Maintenance Checklist page number 1.

Date:_________ Store Location:___________________ Store #_______

Completed by:______________________________________

Before performing any maintenance perform proper lock-out / tag-out procedure!

Check

Off

Perform Daily Inspection

Using the checklist, inspect the mechanical room & tunnel, then run a test car

EQUIPMENT ROOM PROCEDURES

High-Pressure Pump Station

Check belts for visible signs of wear

Verify pump oil is dark green, not milky or black & is at correct level

Verify correct operating pressure (800 psi)

Check tank for sediment or debris

Listen for chatter or cavatation from pump

Air Compressor

Drain water from tank

Check site glass to ensure oil is not milky or black

Alternate air compressors with shut off

Hot Water Boiler

Confirm that the unit is running

Floor Heat Boiler

(If applicable in cold weather)

Confirm that the unit is running and appropiate antifreeze level in sight-glass

Air Manifold System

Listen for air leaks

Drain water from reservoir

Add oil to oil reservoir (if needed)

Check regulators for accurate operating pressures

Hydrominders

Check for smooth operation of floats

Check for air gaps in feed lines. Bleed if necessary.

Water Conditioning

Test water from softener for hardness (prep gun reservoir)

Top off salt in brine tank

Test TDS level of Spot Free water

Weekly Maintenance Checklist For Site Personnel