HTML Preview Temperature Control Chart page number 1.

1

Control Chart

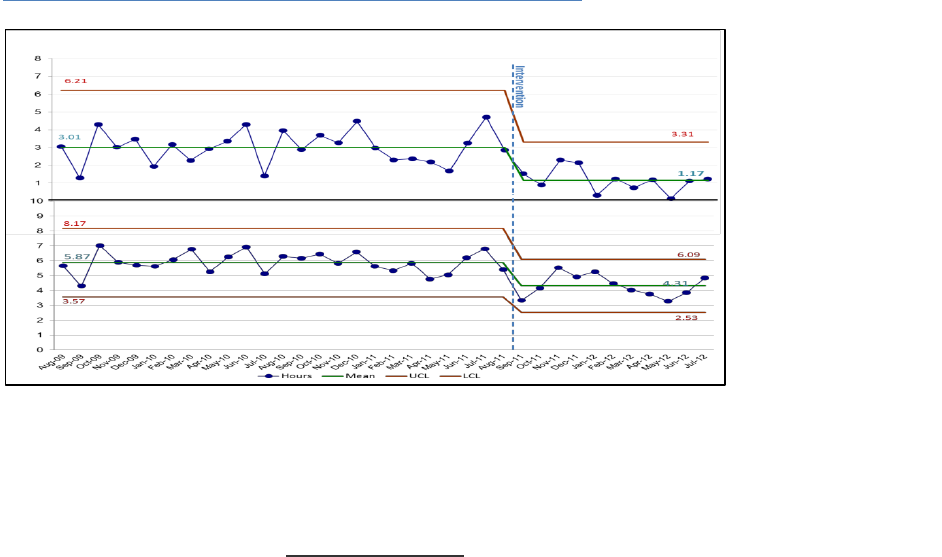

A control chart (also known as a Shewhart Chart) is a graphical display of data plotted over

time. It is a simple tool for understanding variation and it has two general uses in an

improvement project: as a tool to monitor process stability/control and as an analysis tool.

These charts help us understand and visualize the impact of different interventions and tests of

change in real-time and over time. Unlike run charts, control charts show if a process is meeting

its control limits and how much variation there is from these control limits. Control charts are

more sensitive in detecting special cause variation than run charts. The horizontal axis is a time

scale (days, weeks, months, quarters, etc.). The vertical axis represents the quality measure

being studied (e.g. infection rate, number of patient falls, readmission rate). The mean is

calculated and used as the chart’s centerline. Upper and lower control limits corresponding to

± 3 sigma limits from the mean provide the basis for accurate analysis. To determine when data

signal an improvement, the control limits and chart rules are utilized. Goal lines and

annotations of changes and other events can also be added to the control chart. Below is an

example of a control chart demonstrating time to treatment.

Figure 2: Average Time from Admission to Antibiotic Treatment

When to Use a Control Chart

As a core tool for improvement projects to

o Accurately assess whether changes you are making are resulting in true

improvement as you make them

To accurately identify variation and avoid incorrect actions

To effectively communicate results of your improvement efforts

How Control Charts Are Constructed

1. Obtain a set of ≥15 data points in time sequence and plot them in a line graph.