HTML Preview Doe Six Sigma page number 1.

ALS

Advanced Logistic Systems

DESIGN OF EXPERIMENTS AND SIX SIGMA METHODS IN

LOGISTICS

Elke Glistau

1

, Norge I. Coello Machado

2

1

Otto von Guericke University Magdeburg

2

Universidad Central „Marta Abreu“ de Las Villas

Abstract: More and more factors have an influence on effectiveness and efficiency in logistical

processes and systems. An important question of science is to identify the most important factors of

control complex logistical processes and systems, to know their levels and influences to control all

things in a right manner. To find the optimum in control there are often a lot of experiments to realize –

practical and theoretical ones. In this field are used the sensitivity analysis as well as simulation and the

Design of Experiments (DoE) too. This is necessary to fast prevent failures and solve problems early.

This task is not an easy one, especially in logistical networks where a failure can have a lot of causes.

In the following some of the connections between the both sciences Quality Management methods and

Logistics are discussed and examples are given to show the synergy and the greater effects which make

the synergy effect possible. (Compare [1] [2]) Two special areas of methods are focused in this paper:

Methods of DoE and of Six Sigma.

Keywords: Logistics, DoE, Design of Experiments, Six Sigma, Quality Management, methods

1. Quality Management methods in the Logistics area

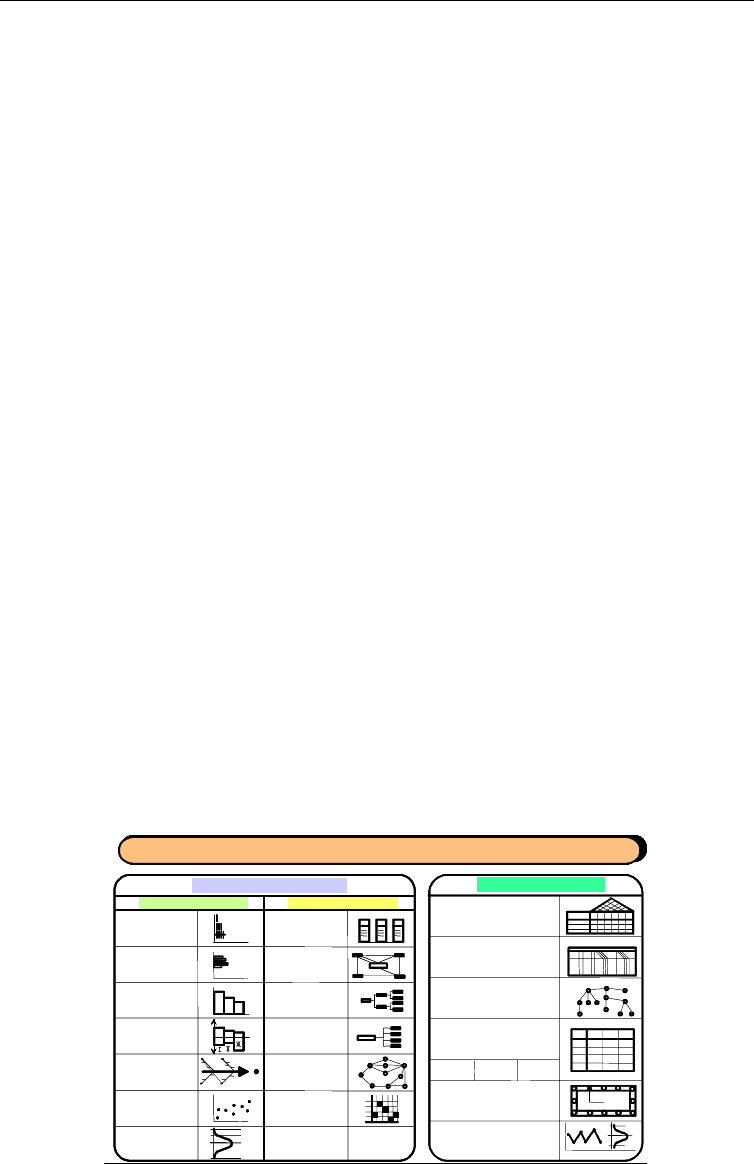

The use of the well known QM-methods makes it possible to recognize failures and their

causes in order to analyze logistical processes and systems (Fig. 1).

Problem resolving techniques

Analytical methods Management methods

Line lists

Histograms

Pareto-

Diagrams

Lorenz-Pareto-

Diagrams

A

B

C

C

B

A

Cause-

effect -

Diagrams

Distribution

diagrams

(Correlation)

Capability

analysis

Affinity-

diagrams

Relations-

diagrams

Process

decision

diagrams

Arrow

diagrams

Matrix

diagrams

Preventive techniques

Quality Function

Deployment

QFD

Failure mode and effect

analysis

FMEA

Failure tree analysis

FTA

Statistical

research methods

classical

Taguchi

Shainin

1

2

3

4

A

B

C

?

Statistical process

control

SPC

Tree-

diagrams

Poka Yoke

+

-

-

+

-

-

+

+

+

-

-

+

Methods, processes and techniques of failure analysis

(with failure source inspection)

Problem resolving techniques

Analytical methods Management methods

Line lists

Histograms

Pareto-

Diagrams

Lorenz-Pareto-

Diagrams

A

B

C

C

B

A

Cause-

effect -

Diagrams

Distribution

diagrams

(Correlation)

Capability

analysis

Affinity-

diagrams

Relations-

diagrams

Process

decision

diagrams

Arrow

diagrams

Matrix

diagrams

Problem resolving techniques

Analytical methods Management methods

Line lists

Histograms

Pareto-

Diagrams

Lorenz-Pareto-

Diagrams

A

B

C

C

B

A

Cause-

effect -

Diagrams

Distribution

diagrams

(Correlation)

Capability

analysis

Affinity-

diagrams

Relations-

diagrams

Process

decision

diagrams

Arrow

diagrams

Matrix

diagrams

Preventive techniques

Quality Function

Deployment

QFD

Failure mode and effect

analysis

FMEA

Failure tree analysis

FTA

Statistical

research methods

classical

Taguchi

Shainin

1

2

3

4

A

B

C

?

Statistical process

control

SPC

Tree-

diagrams

Poka Yoke

+

-

-

+

-

-

+

+

+

-

-

+

Methods, processes and techniques of failure analysis

(with failure source inspection)

Figure 1. Overview of some important quality management methods [3]