HTML Preview Technical spec sheet example page number 1.

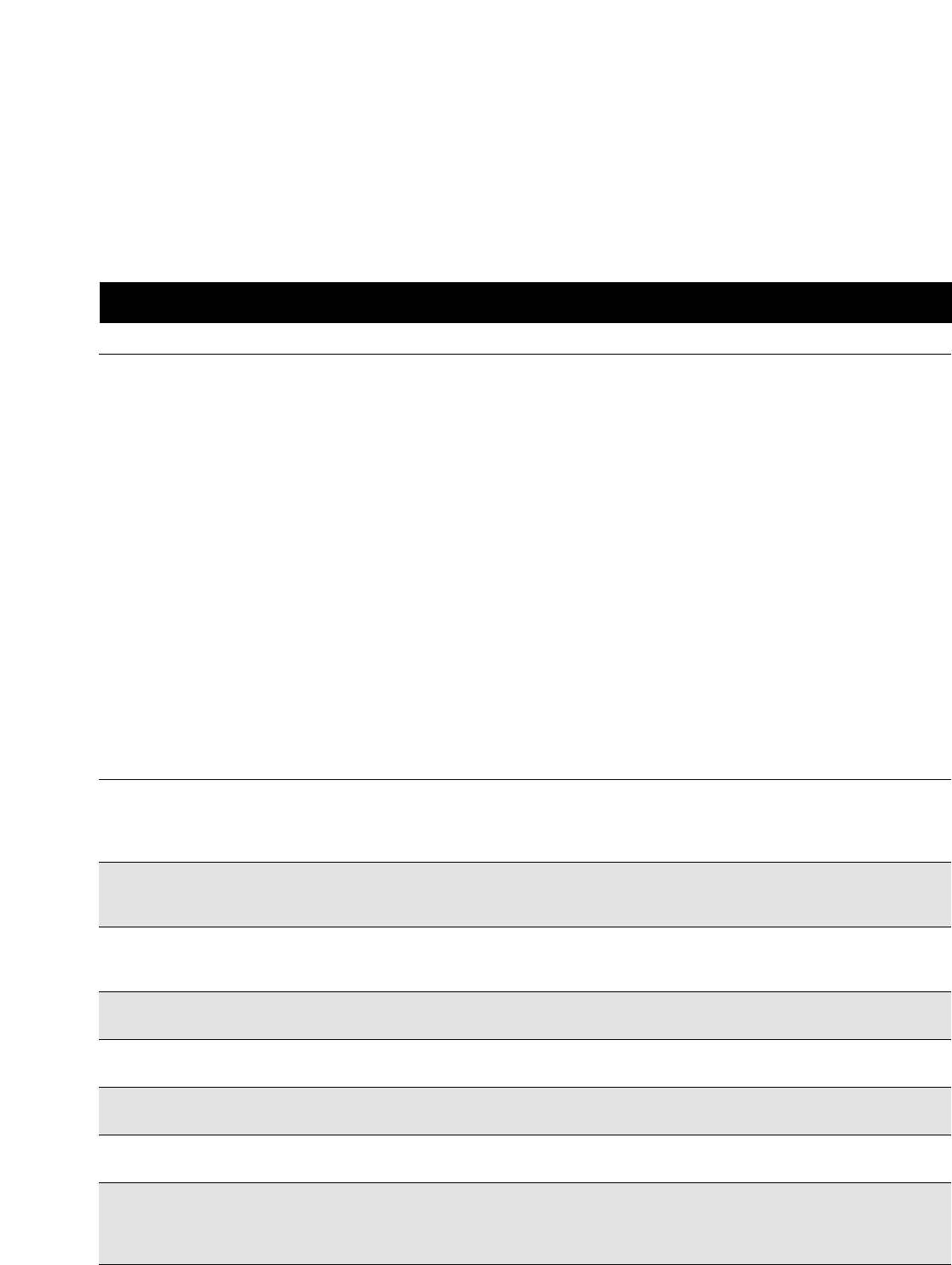

Adhesive Adhesive Liner Liner

Product Type/ Thickness

2

Color, Type, Caliper

3

/

Number Color

1

(mils, mm) Print Liner Release

4

3M™ Adhesive Transfer 200MP/ 2.3 mils Tan, 58#, Polycoated Kraft, 4.2 mils

Tape 467MP Clear (0.06 mm) “3M 467MP 50 grams/inch

200MP Adhesive”

3M™ Adhesive Transfer 200MP/ 5.2 mils Tan, 58#, Polycoated Kraft, 4.2 mils

Tape 468MP Clear (0.13 mm) “3M 468MP 50 grams/inch

200MP Adhesive”

3M™ Adhesive Transfer 200MP/ 2.3 mils Clear, Polyester (PET), 2.0 mils

Tape 467MPF Clear (0.06 mm) No Print 20 grams/inch

3M™ Adhesive Transfer 200MP/ 5.2 mils Clear, Polyester, 2.0 mils

Tape 468MPF Clear (0.13 mm) No Print 20 grams/inch

3M™ Adhesive Transfer 200MP/ 2.3 mils White, polycoated glassine paper 3.5 mils

Tape 467MPR Clear (0.06 mm) printed with white 3M logo 55 grams/inch

3M™ Adhesive Transfer 200MP/ 5.2 mils White, polycoated glassine paper 3.5 mils

Tape 468MPR Clear (0.13 mm) printed with white 3M logo 55 grams/inch

3M™ Adhesive Transfer 200MP/ 2.3 mils 1) Tan, 58#, Polycoated Kraft, 1) 4.2 mils

Tape 7952MP Clear (0.06 mm) “3M 200MP” 50 grams/inch

2) Tan, 58# PCK 2) 4.2 mils

12 grams/inch

Constructions

3

High Performance Adhesive Transfer

Tapes with Adhesive 200MP

467MP • 468MP • 467MPF • 468MPF • 467MPR • 468MPR • 7952MP • 7955MP

7962MP • 7965MP • 9172MP • 9172PT • 9185MP • 9188 • 9667MP • 9668MP • 9676

Product Description

3M™ Adhesive 200MP is a popular choice for graphic attachment and membrane

switch applications because it has excellent quality, consistency and durability. In

addition, as a result of 3M’s innovative, proprietary process, 3M adhesive 200MP also

offers the following excellent performance characteristics.

Clarity (virtually free of vapor inclusions that are commonly found in adhesives

produced by the traditional solvent coating technique).

Excellent high temperature performance as well as excellent shear strength (that

minimizes edge lifting and slippage of parts).

Excellent resistance to harsh environments; this adhesive can withstand splashes of

organic solvents, weak acids and bases and salt water, cleaning solutions, germicidals,

disinfectants, oils, etc. In addition, it performs well after exposure to humidity and

hot/cold cycles.

Provides some initial repositionability when bonding to plastic parts (not metal) which

allows graphic parts to be lifted and repositioned if initial alignment is incorrect.

Finally, this adhesive family is provided with a variety of liner configurations to help

ensure excellent process flexibility.

Technical Data October, 2003