Wekelijkse onderhoudschecklist

Opslaan, invullen, afdrukken, klaar!

De beste manier om een Wekelijkse onderhoudschecklist te maken? Check direct dit professionele Wekelijkse onderhoudschecklist template!

Beschikbare bestandsformaten:

.pdf- Gevalideerd door een professional

- 100% aanpasbaar

- Taal: English

- Digitale download (23.29 kB)

- Na betaling ontvangt u direct de download link

- We raden aan dit bestand op uw computer te downloaden.

Zakelijk wekelijkse checklist controleren Lucht Inspecteren Voorbeeld van wekelijkse checklist Slijtage

How to draft a Weekly Maintenance Checklist? An easy way to start completing your document is to download this Weekly Maintenance Checklist template now!

Every day brings new projects, emails, documents, and task lists, and often it is not that different from the work you have done before. Many of our day-to-day tasks are similar to something we have done before. Don't reinvent the wheel every time you start to work on something new!

Instead, we provide this standardized Weekly Maintenance Checklist template with text and formatting as a starting point to help professionalize the way you are working. Our private, business and legal document templates are regularly screened by professionals. If time or quality is of the essence, this ready-made template can help you to save time and to focus on the topics that really matter!

Using this document template guarantees you will save time, cost and efforts! It comes in Microsoft Office format, is ready to be tailored to your personal needs. Completing your document has never been easier!

Download this Weekly Maintenance Checklist template now for your own benefit!

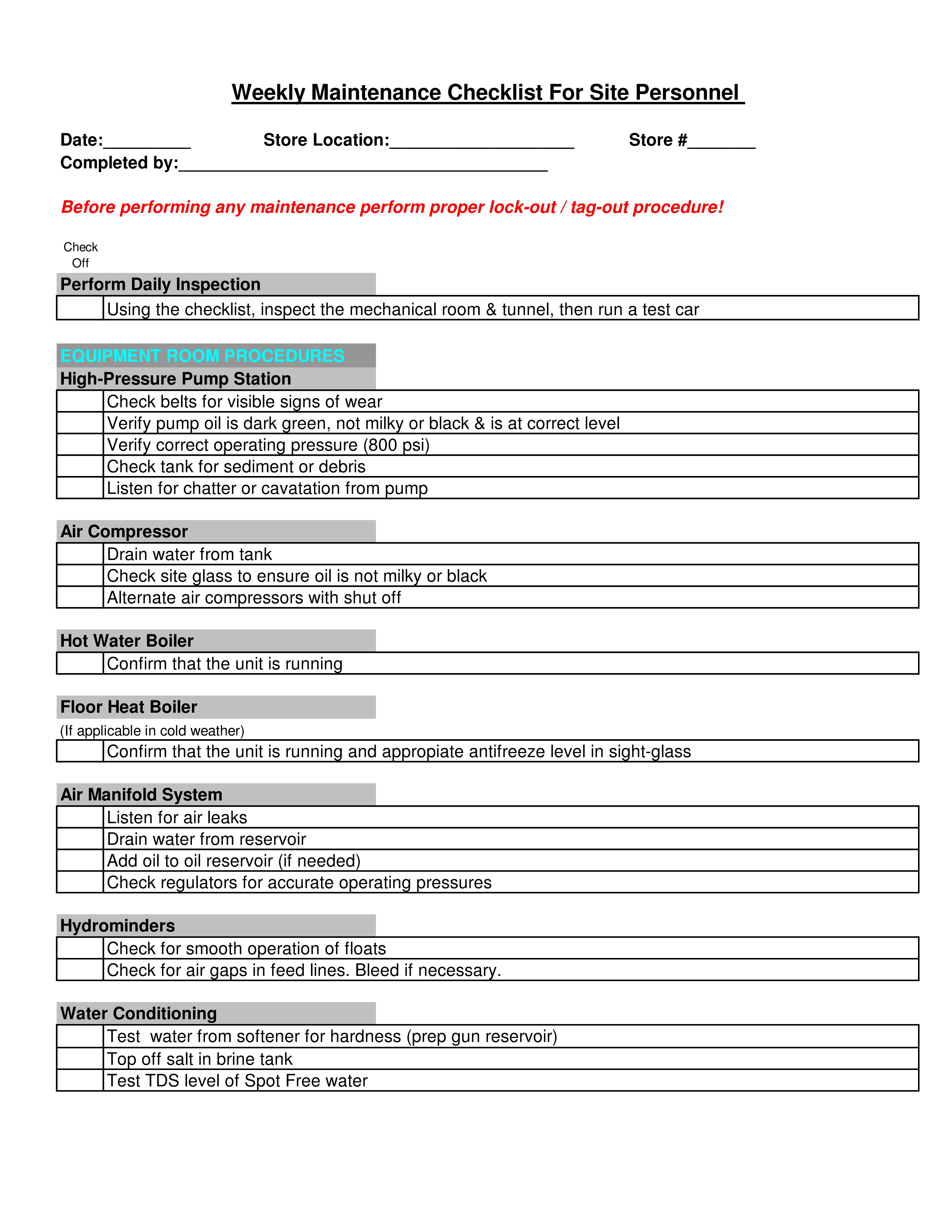

Weekly Maintenance Checklist For Site Personnel Date: Store Location: Completed by: Store Before performing any maintenance perform proper lock-out / tag-out procedure Check Off Perform Daily Inspection Using the checklist, inspect the mechanical room tunnel, then run a test car EQUIPMENT ROOM PROCEDURES High-Pressure Pump Station Check belts for visible signs of wear Verify pump oil is dark green, not milky or black is at correct level Verify correct operating pressure (800 psi) Check tank for sediment or debris Listen for chatter or cavatation from pump Air Compressor Drain water from tank Check site glass to ensure oil is not milky or black Alternate air compressors with shut off Hot Water Boiler Confirm that the unit is running Floor Heat Boiler (If applicable in cold weather) Confirm that the unit is running and appropiate antifreeze level in sight-glass Air Manifold System Listen for air leaks Drain water from reservoir Add oil to oil reservoir (if needed) Check regulators for accurate operating pressures Hydrominders Check for smooth operation of floats Check for air gaps in feed lines..

DISCLAIMER

Hoewel all content met de grootste zorg is gecreërd, kan niets op deze pagina direct worden aangenomen als juridisch advies, noch is er een advocaat-client relatie van toepassing.

Laat een antwoord achter. Als u nog vragen of opmerkingen hebt, kunt u deze hieronder plaatsen.