Equipment Repair Process

Sponsored Link免费模板 保存,填空,打印,三步搞定!

Download Equipment Repair Process

微软的词 (.doc)免费文件转换

- 本文档已通过专业认证

- 100%可定制

- 这是一个数字下载 (98 kB)

- 语: English

Sponsored Link

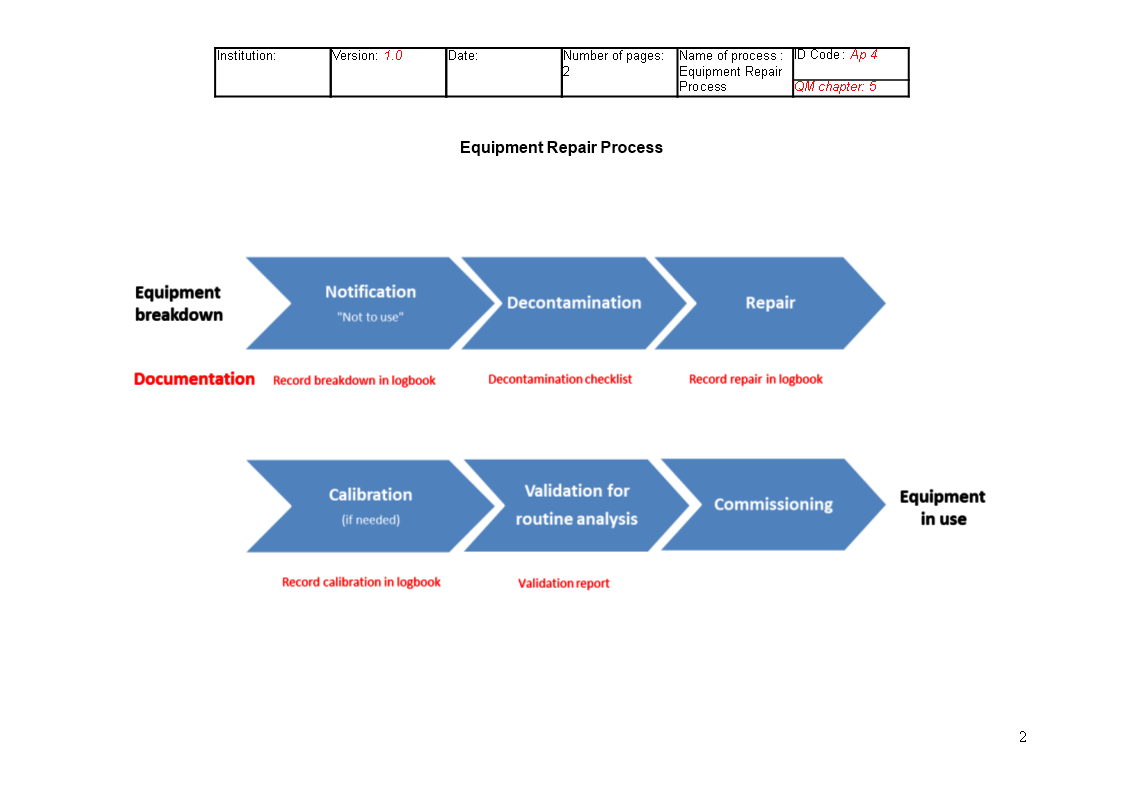

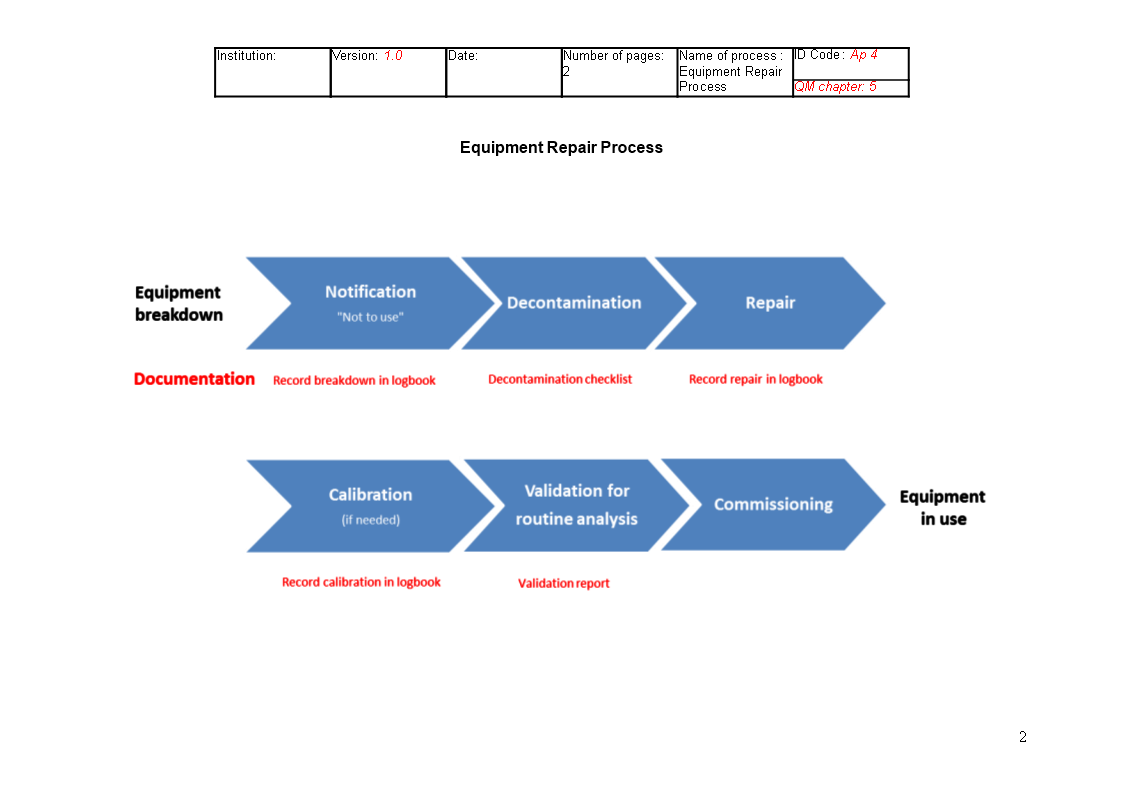

How to create a Repair Procedure for Equipment in case something breaks down? Have a look at this Quality Management SOP template that includes the process from equipment breakdown until commissioning.

This quality SOP describes the equipment repair process, including equipment breakdown, notification, decontamination, repair, calibration, validation for routine analysis and commissioning. The document template is based on international standards and provides an example that shows how to write policies and procedures that together will form your Quality Management System (QMS). The size and complexity of your organization and its individual processes will determine if this Equipment Repair Process is useful for your organization. It will support and improve the existing Quality Management System works and controls that are already in place to manage each process. It demonstrates the commitment to meeting your customer expectations’ by delivering quality products and/or services.

By implementing this Equipment Repair Process in your organization, you will improve your Quality Management System or compliance with QMS systems such as ISO 9001. A QMS in its basic concept is not too complicated. Many organizations are struggling with the idea they are required to implement a lot of bureaucratic documents and protocols and ask themselves, whether or not it’s worth trying to develop such a seemingly complicated system. It is not necessarily a complicated system that is needed. Guidance on having clear and concise communication throughout the organization’s documents and between departments does also not have to be elaborated.

It’s important that you can set expectations from both management and employees and you follow a framework, such as ISO 9001, in order to prevent making it too complicated and ensuring you have an integrated solution for the whole company. When you follow this approach, and you determine processes and their interactions, inputs, and outputs in your organization.

Download this Equipment Repair Process now and you will find out it’s very helpful for your company to improve the quality level by measuring, monitoring, and reporting about the performance of the business processes and gradually improve the company output. Other primary quality control tools, such as checklists, fishbone diagrams, control charts, manuals, charts, reports, can be found here: Quality Management Templates.

DISCLAIMER

Nothing on this site shall be considered legal advice and no attorney-client relationship is established.

发表评论。 如果您有任何问题或意见,请随时在下面发布

相关文件

Sponsored Link